Product Info

Horizontal, vertical, exhaust air, table-top units, isolators

Description

A safety cabinet (class 2 and 3) or laminar flow table is the smallest form of cleanroom. This safety cabinet is usually only designed for one or a maximum of two people and differs mainly in its protective function. They work inside with low-turbulence displacement flow and achieve air cleanliness up to class ISO 1 and A according to GMP at working height.

Typically, these systems work largely with recirculated air to avoid unnecessary strain on the HEPA filters. Due to the different types of fresh air supply, there are workbenches that are operated in negative pressure (fresh air via the front opening) (product and personnel protection), but also others that are in positive pressure (fresh air at the top) in the work area and are therefore only designed for product protection (table-top LF). Digestors (class 1) are pure exhaust air systems with negative pressure inside and are used purely for personal protection.

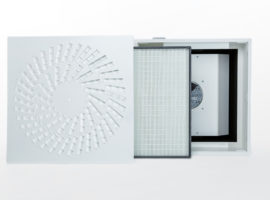

The isolator is a special form of safety cabinet. The product is separated from the person by a barrier. The product inside can be manipulated with gloves permanently attached to the front. The product is fed in and out through lateral product locks.

Advantage over conventional systems: Higher product and personal safety, low requirements for the front area and working person Disadvantages: High costs, awkward working The application is limited to activities with low space requirements. The advantage of safety cabinets is that a small but very high-quality cleanroom area is created at low investment cost. However, the additional heat load on the room must be taken into account. Some systems also require an exhaust air system (e.g. cytostatic workbenches).