Product Info

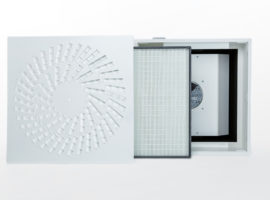

The turnkey operating theater incl. walls, ceiling, floors, OR light, media bridge, air conditioning, TAV ceiling, doors

Description

In contrast to "room in room systems", the cleanroom is defined as a whole, which must have a certain air purity. A defined limit value for particles or CFU (germ-forming units) must be maintained at every point in the room. This requires that all materials used also comply with this class. The main standard currently used worldwide for these limit values is ISO 14644-1 with ISO classes from 1 to 9. The GMP guideline also refers to the class limits of ISO 14644-1.

Which flow systems are suitable for the room depends on many factors. Most attention is paid to the work process, where there is a direct risk of contamination of the product (cause: man and machine). Other factors such as: clothing used, materials in the room, room geometry, thermal conditions, vibrations and so on.... must also be taken into account in the design.

In the classes with lower air purity requirements (ISO 7, 8 and 9), turbulent mixed ventilation with ceiling swirl diffusers and HEPA filters is usually used and the air quality in the room is controlled via the air exchange rate. A constant positive pressure in the cleanroom is essential. Class ISO 6 is a transition class that is often implemented with directed airflow. Alternative flow forms such as baffle plates or perforated plate diffusers should not be forgotten, but displacement outlets in the floor area can also be used cost-effectively and practically.

Classes ISO ≤ 5 are usually designed with low-turbulence displacement flow. The higher the requirements, the higher the filter class H13 to U17 with PTFE and activated carbon combined. It is important to separate people and product in these lower classes as far as possible.