Product Info

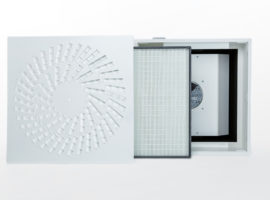

Process enclosures with low-turbulence flow (minienvironment, wet workstations, filter fan units)

Description

Our Table Air is a mini-environment that represents a middle ground between a safety cabinet and a cleanroom cabin. The difference to a safety cabinet lies in the fact that the product or process to be protected is already specified in a minienvironment and the enclosure (frame with glass walls, lighting, etc.) and the cleanroom components (filter fan units, extraction, etc.) are built to suit the process.

In most cases, such a minienvironment is sealed off on all four sides with transparent walls (glass, PP, acrylic, etc.) and a filter fan module flows vertically through it from above. The clean air is thus released into the room via the work process and further downwards via perforated or open areas. The large-area flow, with air filtered by HEPA filters and the resulting overpressure inside the Minienvironment, ensures excellent clean room classes "at rest" and "in operation". Achieving a low-turbulence displacement flow (laminar flow) in the interior is not absolutely necessary and usually not even possible.

In these cases, the aim must be to flow through the indoor area with as high an air exchange rate as possible and to avoid dead zones and air turbulence. Horizontal, diagonal and also bottom-up flows are also possible if they produce a better flow result in the indoor area. As a rule, this protects largely automated work processes that do not require constant human intervention.

The great advantage of minienvironments is that a very good cleanroom class, e.g. ISO 1 in accordance with ISO 14644, can be achieved with very little cost and space requirement thanks to the "room-in-room" insulation: ISO 1 according to ISO 14644 can be achieved.